ISO 21940 Balance Quality G Grades

ISO 21940 Balance Quality G Grades are used to calculate balance tolerances in conjunction with the rotor weight and service speed (RPM).

Guidance for balance quality grades for rotors with rigid behaviour

BALANCE QUALITY GRADE G |

MAGNITUDE e per Ω mm/s |

MACHINERY TYPES - GENERAL EXAMPLES |

G 4000 |

4 000 |

|

G 1600 |

1 600 |

|

G 630 |

630 |

|

G 250 |

250 |

|

G 100 |

100 |

|

G 40 |

40 |

|

G 16 |

16 |

|

G 6,3 |

6,3 |

|

G 2,5 |

2,5 |

|

G 1 |

1 |

|

G 0,4 |

0,4 |

|

NOTE 1. Typically, completely assembled rotors are classified here. Depending on the particular application, the next higher or lower grade may be used instead. For components, see clause 9.

NOTE 2. All items are rotating if not otherwise mentioned (reciprocating) or self-evident (e.g. crankshaft drives).

NOTE 3. For some additional information on the chosen balance quality grade, see Figure 2 which contains generally used areas (service speed and balance quality grade G) based on common experience.

NOTE 4. For some machines, specific International Standards stating unbalance tolerances exist.

NOTE 5. The selection of a balance quality grade G for a machine type requires due consideration of the expected duty of the rotor when installed in situ which typically reduces the grade to a lower level if lower vibration magnitudes are required in service.

NOTE 6. The shaft height of a machine without feet, or a machine with raised feet, or any vertical machine, is to be taken as the shaft height of a machine in the same basic frame, but of the horizontal shaft foot-mounting type. When the frame is unknown, half of the machine diameter should be used.

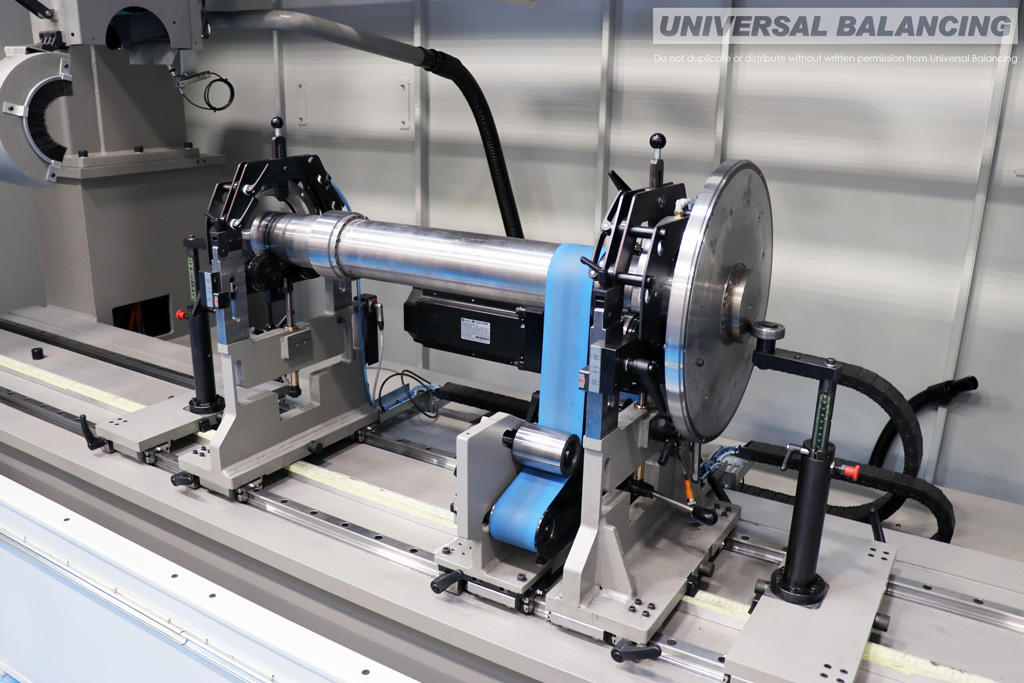

Static and dynamic balancing of your parts

We provide static and dynamic balancing services to repairers and large companies across UK and Europe who require crankshaft balancing, fan balancing, shaft balancing, and much more. We have the equipment and experience to balance almost any rotating component quickly and to a high standard.

We use several vertical and horizontal balancing machines from the balancing technology experts Burke Porter to provide you with guaranteed high quality precision balancing solutions for your parts.

How can we help you?

If you know what you want, use the Free Quote button to get started.

If you need a chat, fill out the form below and our experts will be in touch.