Horizontal balancing machines

We offer a full range of high specification horizontal balancers for all industries, supporting a wide range of applications, balancing rotors weighing up to 20,000 kg as standard. Special designed solutions are available for rotors outside of this range.

Balancers are available as stand-alone for manual use, or fully automated to include operate free correction and loading using robot or gantry loading to fully integrate with your production line.

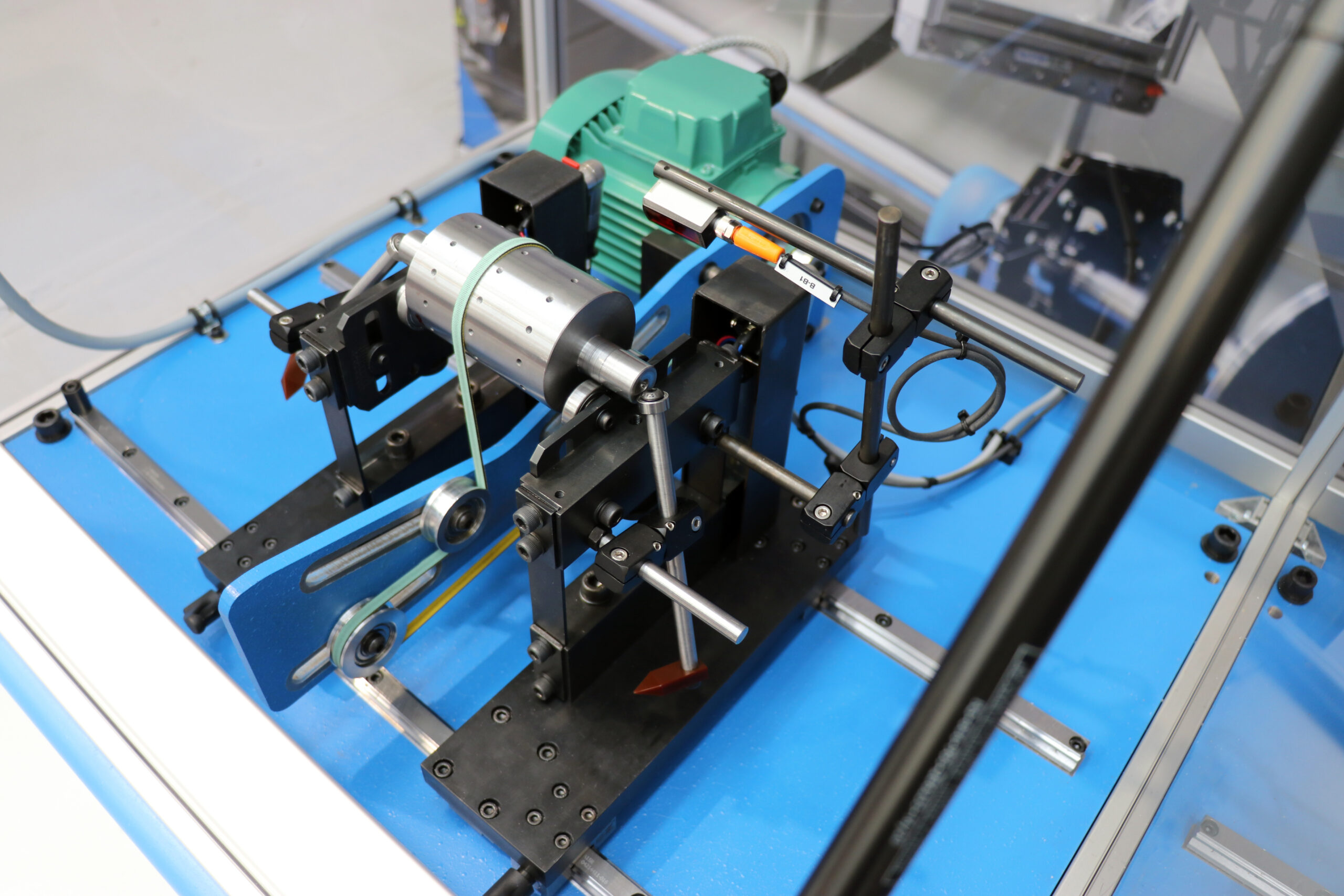

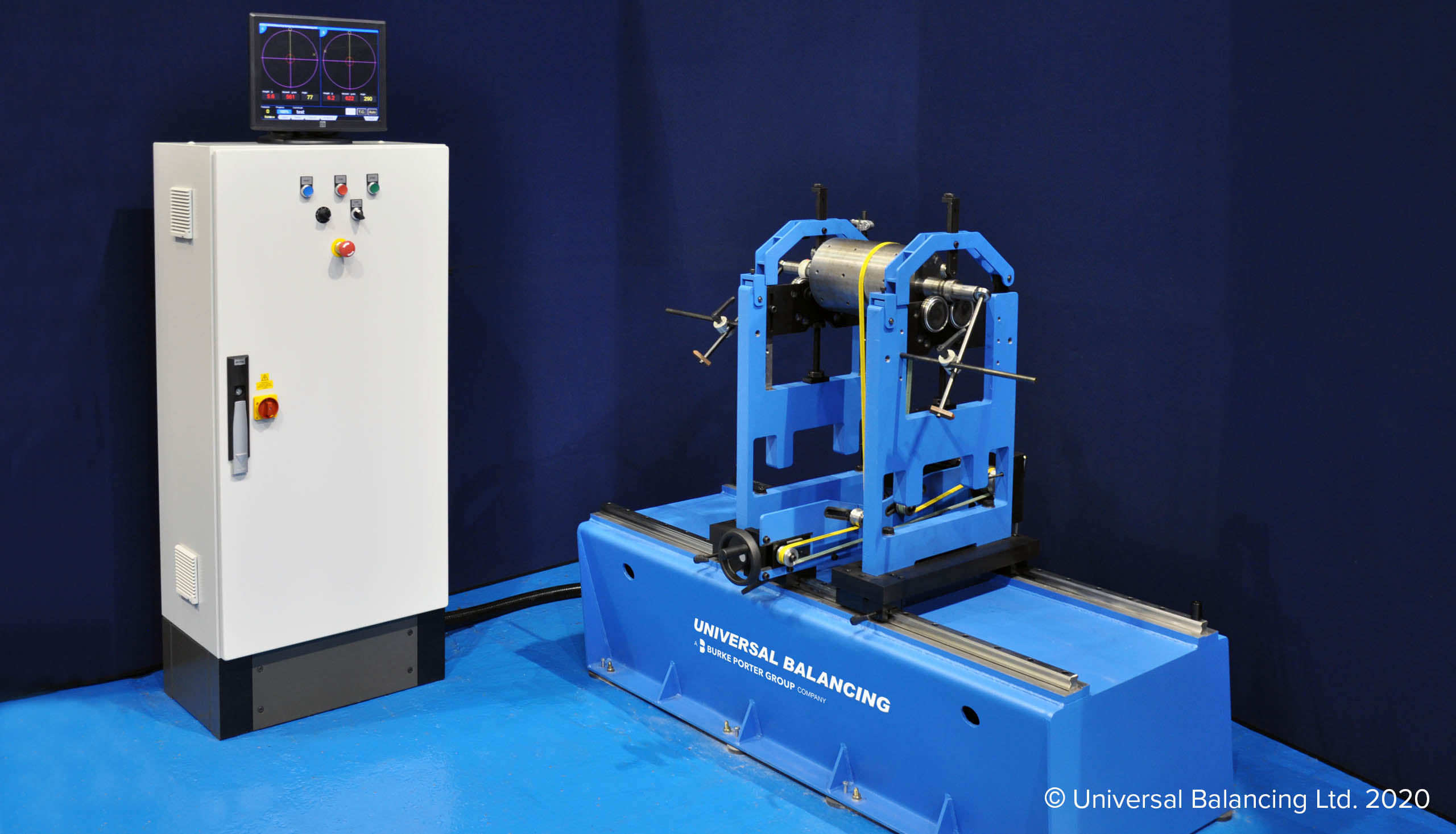

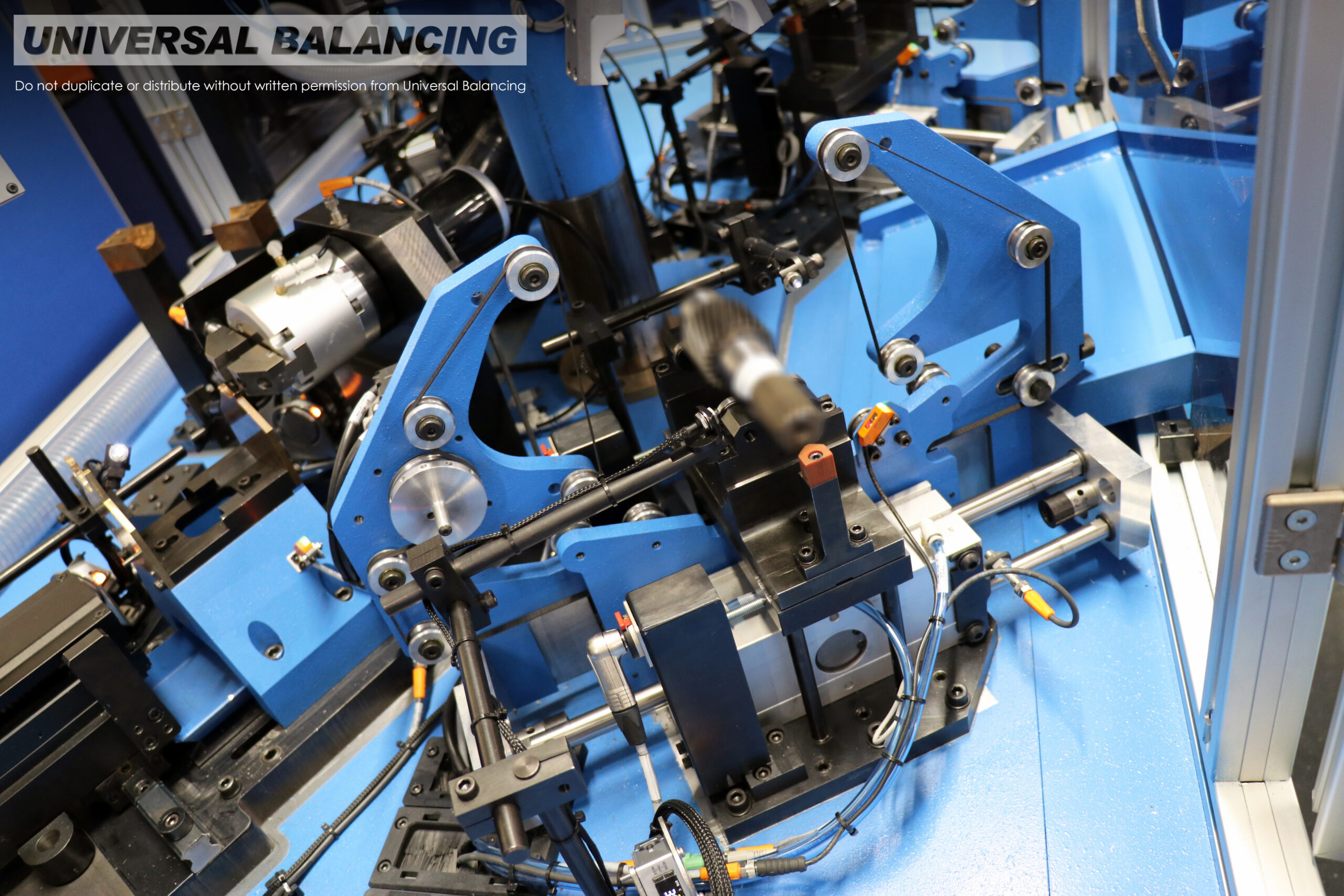

Electric Motor Balancer

Our eRotor balancing machine range is unbeatable in the global market for ultra-high accuracy electric motor balancing with industry leading cycle times.

We have automatic and manual configurations to suit any production volume and a fully automated machine changeover option for error free changeover to another part type in seconds.

These machines can be supplied as audit only stations or with manual or automatic dual drilling for fast and accurate correction. Other methods of correction are available such as mill, laser welding and other special proprietary technologies.

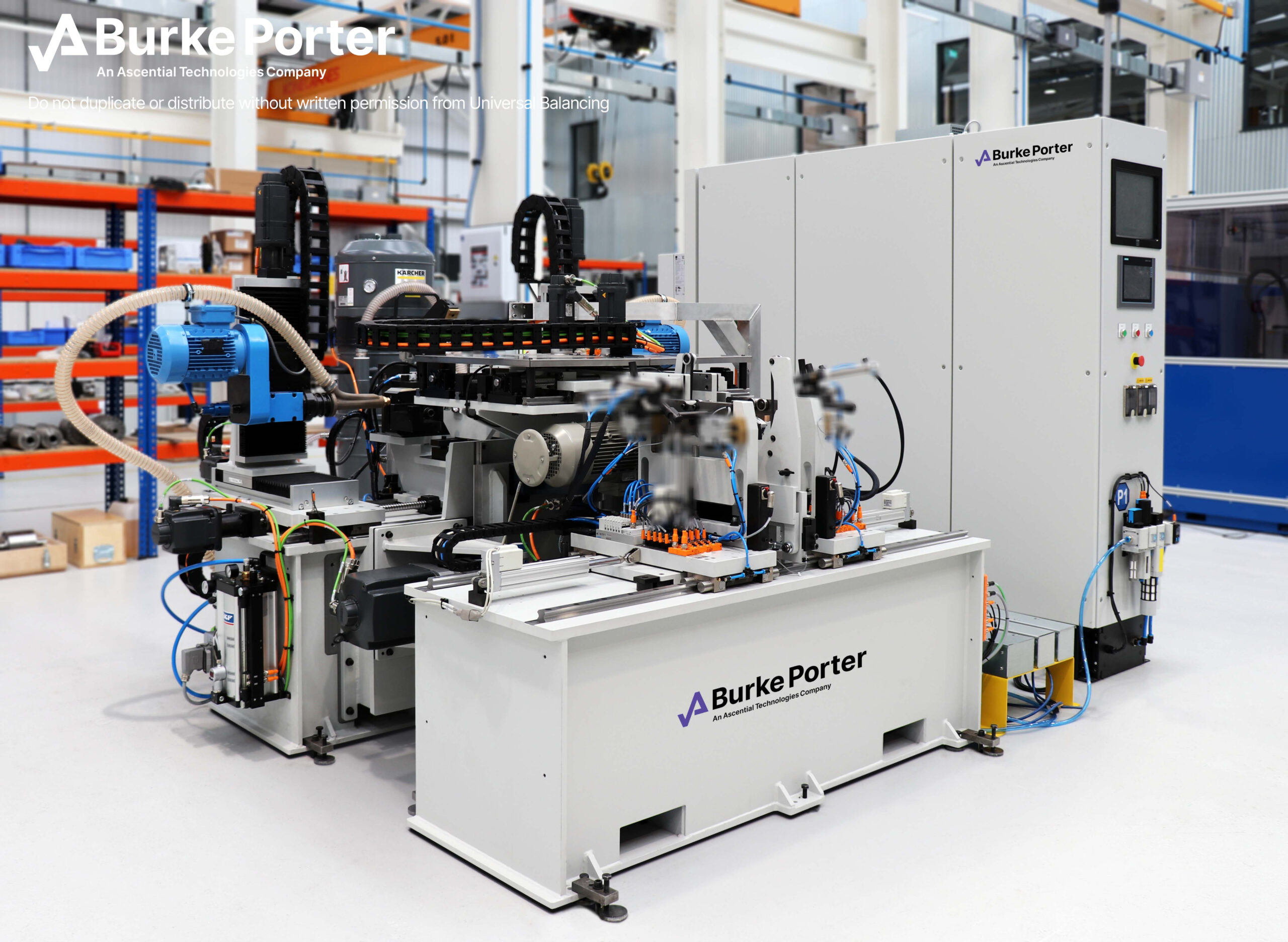

Crankshaft Balancer

We offer single and multi-station crankshaft balancer both with a fully automated operating sequence and optional automatic loading by interfacing your conveying equipment to further increase production throughput. We have crankshaft balancer for all types of light and heavy-duty crankshaft, inline, V and single cylinder.

We also provide mass centering machines for raw cast crankshafts with optional feedback from production lines to fine tune the machine process.

Pump Impeller Balancer

Our horizontal pump impeller balancers can balance a wide range of pump impellers weighing up to 20,000kg.

Easy to load and setup and even easier to use with a full range of correction methods available. Typically supplied as manual machines but automation options are available to help reduce cycle times and improve balancing quality.

We also have a range of vertical machines for pumps to accommodate for different part type requirements.

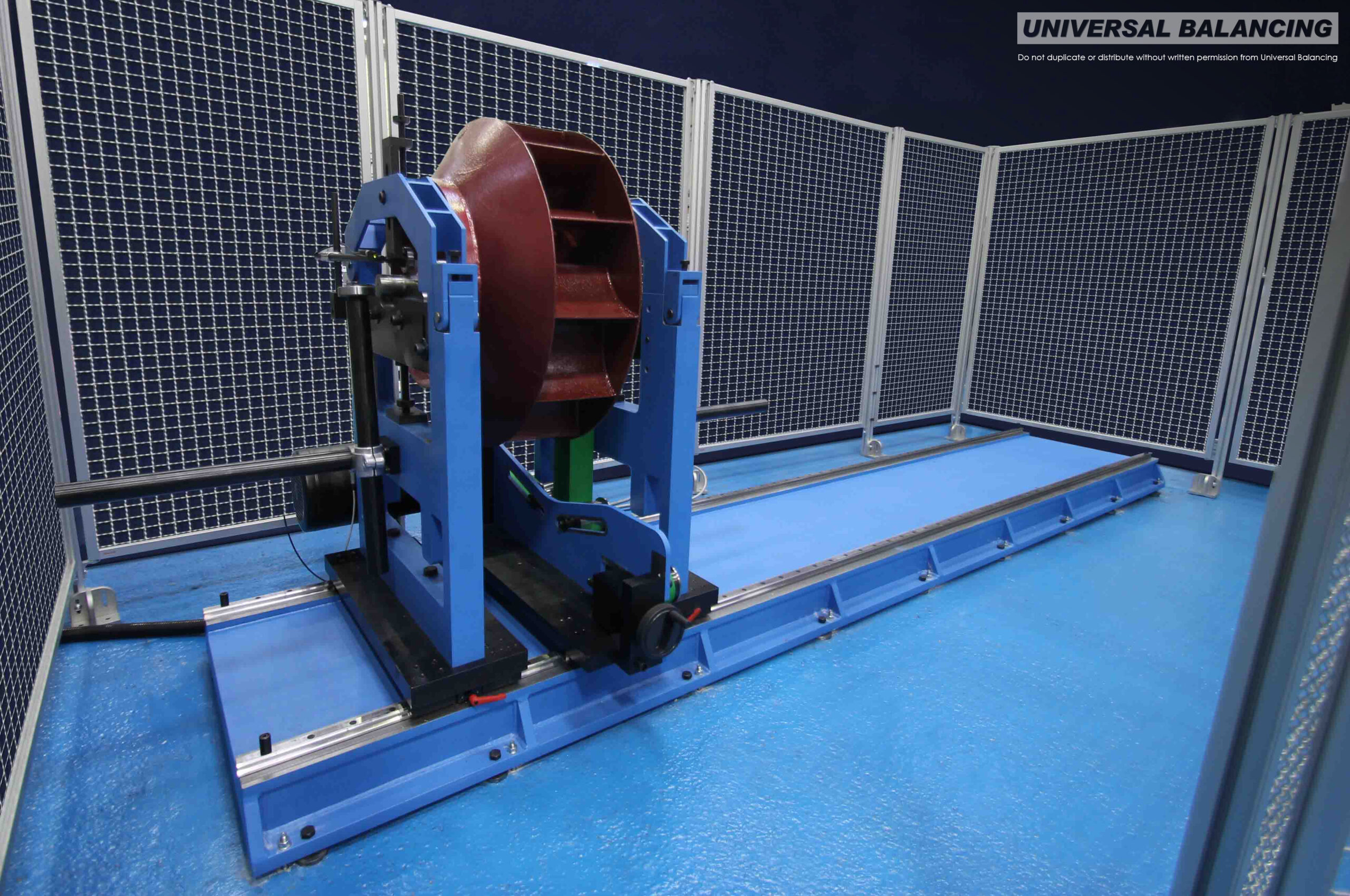

Fan Balancer

We offer a flexible range of high specification fan balancers and blower balancers for any type and size. These include vertical rotating, non-rotating (static), horizontal cradle or horizontal spindle balancing machines to suit the application.

We can provide tooling to allow fans to be driven by their own motor and bi-directional drives to spin counter to the resistance pattern of the blades. We also have special balance processes to settle the blades into their running positions.

Transmission components Balancer

Our transmission balancers accommodate a wide range of components including transmission shafts, plates, gears, and hubs.

These balancers exceed industry standard requirements for accuracy and repeatability and deliver with industry leading cycle times.

Available with automatic drill or mill correction and cut start detection feedback to ensure quality unbalance correction.

We also have a range of vertical machines for transmission components to accommodate for different part type requirements.

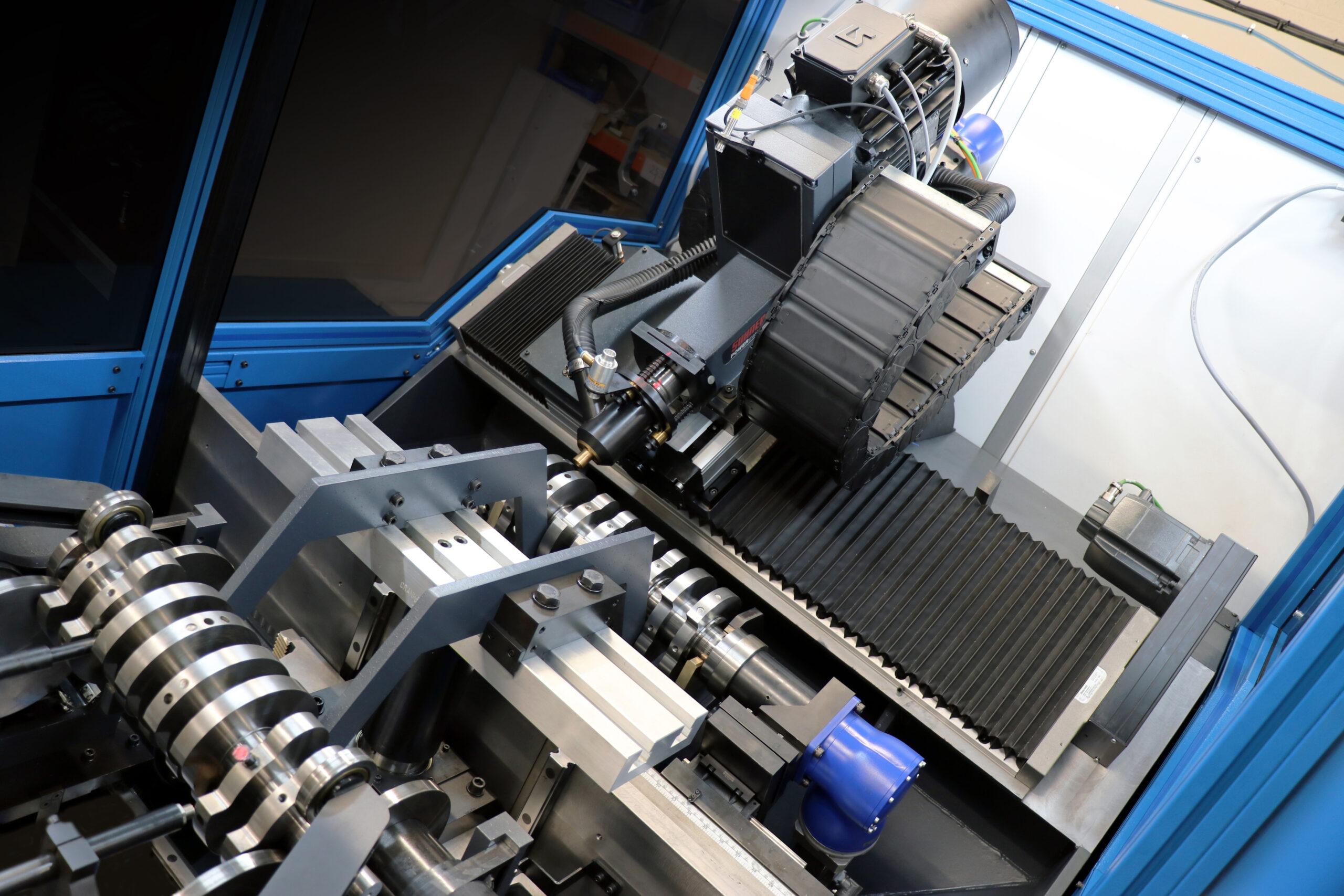

Turbine Component Balancer

Our horizontal balancing machines are perfect for turbine balancing of any size. Typically supplied as a manual machine, it is simple to load and operate with minimal maintenance required.

Let’s talk about your project

We would love to help you with your specialist application, enter your details below and a dedicated balancing engineer will be in touch – no obligation.